See how Sciath AiM Forge uses metal 3D printing to produce reliable, high-performance suppressors for their customer Irregular Design Group.

Sciath AiM Forge leverages metal 3D printing to manufacture precision firearm suppressors for Irregular Design Group. Using additive manufacturing, the company delivers durable, repeatable parts while rapidly adapting designs and shortening production times.

In this video, you'll see:

At the beginning, there is your use case, for which you must create a component design in a CAD program.

If your component has support structures, now is the time to remove them. Optionally, further finishing steps are possible, such as sandblasting, polishing, or grinding.

MONE is the digital platform for location-independent monitoring and control of your MPRINT.

The problem of unsafe and unclean powder management is solved with the BOLDSERIES by the cartridge system.

Properties:

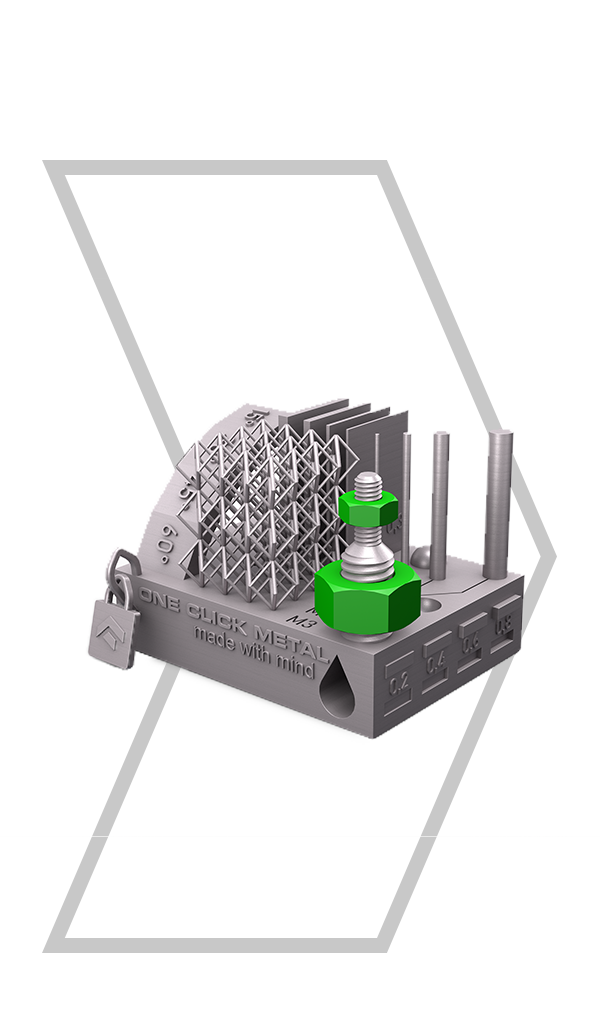

Application example:

Properties:

Application examples:

Properties:

Application examples:

Properties:

Application examples:

Properties:

Application examples:

Properties:

Application examples:

ALUMINUM - A6061-RAM2 - Lightweight yet strong, this material offers an excellent strength-to-weight ratio, corrosion resistance, and improved thermal conductivity. This makes it ideal for aerospace, automotive, and high-performance industry applications. Additionally, components in A6061-RAM2 can be anodized to create an appealing look.

COBALT CHROME - 2.4979 CoCr28Mo6 - Known for its exceptional strength, corrosion resistance, and temperature stability, this material is perfect for medical implants, components in aerospace, and high-wear applications.

Fill out the form below for an expert to connect with you. Or sign up for a meeting with an expert by clicking here.

Their product solutions are based on four approaches, which they have identified as the solution to their customers' needs:

To make your entry into metal 3D printing as uncomplicated as possible, ONE CLICK METAL has put together a complete package. It includes everything you need for a technology start — with transparent costs and an unbeatable price-performance ratio.

Total package includes: